Formerly

Save up to 70% over New with Refurbishing

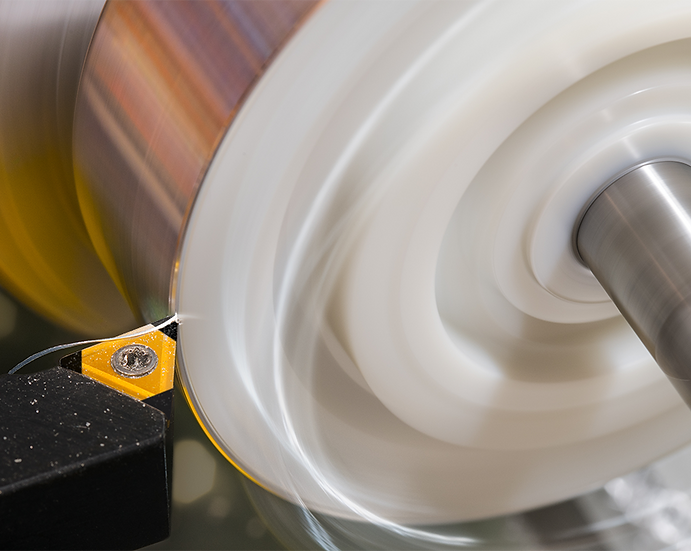

We are a fabricator and rebuilder of CBN, PCD and CVD cutting tools. With a wide variety of standard turning inserts, as well as specialty tools for especially troublesome applications, such as:

-

Profiling and turning tools for large OD rolls, pipe and can dies from tool steels and sintered carbide.

-

Special inserts for efficient turning of powdered metals.

-

Boring bars and inserts for small hole boring in hard or abrasive materials

-

hardened steel

-

carbide

-

cast iron

-

-

Boring bars and inserts for small hole boring in non-ferrous materials

- aluminum

-

copper

-

bronze

-

plastic

In addition to fabricating new tools, we stand out by offering comprehensive insert rebuilding services—a rarity in the industry. Our dedication to rebuilding is on par, if not greater, than our commitment to new tool fabrication.

We prioritize maximizing the performance and lifespan of your tooling whenever feasible. Furthermore, our swift turnaround times ensure minimal investment in high-cost tooling, providing you with both efficiency and cost-effectiveness.

Contact us to discuss your options today

SE@H3DTool.com

Regrinding Inserts

One of the most straightforward and cost-effective methods for rejuvenating your tooling inserts is through regrinding. By precisely measuring the wear on your insert, we skillfully grind back the cutting edge to eliminate any signs of wear. Any edge preps that were present are meticulously reapplied, resulting in a restored cutting tool at a fraction of the cost of a new one.

Retipping Inserts

When your insert has reached the end of its service life, fear not. Through the retipping process, we expertly remove the used tip from its carbide body. A fresh tip is then precisely re-brazed onto the tool, eliminating the need for a full replacement and saving you valuable resources all while taking your insert to new tool specifications.

Methods of Servicing Tools

Application | CBN Grades | PCD Grades | CVD |

|---|---|---|---|

Ideal for non-ferrous materials including green/sintered carbide, green ceramics and graphite | QRDX | ||

Extremely fine particle size for non abrasive applications requiring a fine cutting edge | QRD03 | ||

Larger particle size for highly abrasive materials, also for sintered carbide up to about

18% binder levels | QRD02 | ||

Excellent all around PCD grade, medium particle size | QRD01 | ||

Higher ceramic content and fine CBN particle size make this grade especially fracture

resistant, especially good for severe interrupted cutting | QRL11 | ||

Low content CBN, higher ceramic component increases toughness - general hard

turning, interrupted cut in tool steels, can be excellent in some iron applications | QRL07 | ||

Extremely wear resistant, good for powdered metals, including high cobalt sintered

carbide, tool steels, hard facing materials, flame spray materials, cast iron | QRH06 | ||

Tool steels, Cast iron, excellent for general turning of tool steels and cast iron. Some prefer QRL11 or QRL07 for interrupted cuts. | QRH08 | ||

Excellent for cast iron, can be used for continuous cut hardened steel | QRH04 |